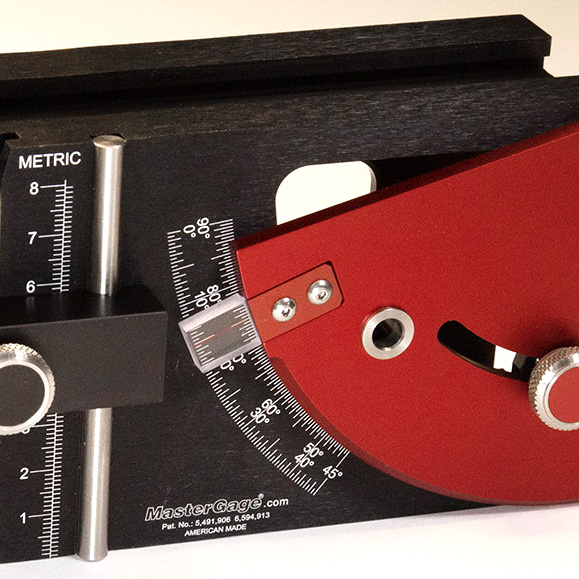

MasterGage Frequently Asked Questions – FAQ

Question:How is the MasterGage/Pro and MasterGage/Classic different from the SuperBar?

Answer:

The MasterGage/Classic and MasterGage/Pro are more powerful tools that can align, calibrate and tune up most any piece of woodworking equipment. The SuperBar was designed specifically for sliding in the miter slot and aligning and tuning the table saw.

Question:

How accurate are the etched scales?

Answer:

To within .002 inch [2/1000].

Question:

My equipment seems to be OK, how do I know I need something like the MasterGage?

Answer:

All of the misalignments on all of your machinery are COMPLETELY INVISIBLE. With the MasterGage System, you will be able to make all of these misalignments completely VISIBLE. With the MasterGage System, you will finally get control of all of your equipment and no matter what machine you are setting up or calibrating, you are always reading the same accurate scales on the MasterGage/Classic or MasterGage/Pro.

SuperBar Frequently Asked Questions – FAQ:

Question:

What is included in the SuperBar package?

Answer:

The package includes:

The SuperBar unit, with all stainless

steel hardware |

Hex wrench for mounting Dial Indicator. |

Precision Dial Indicator, 1.0 inch travel,

with accuracy to .001 inch [1/1000] |

Hex wrench for the adjustment system. |

| 1.0 inch long stainless steel extension stem |

Detailed illustrated instructions |

| 2.0 inch long stainless steel extension stem |

|

Question:

What saws will the SuperBar work with?

Answer:

It will work with all saws having a 3/4 wide x 3/8 deep miter slot. This includes Delta, Jet, Powermatic and General machines.

Question:

I have a Sears saw, will it work on my saw?

Answer:

Yes, the Sears has a.740 x 3/8 deep wide miter slot. We have designed the SuperBar to accommodate both the standard 3/8 x 3/4 miter slots AND the Sears saws.

Question:

Do you have a ShopSmith version?

Answer:

Yes, and we offer this version at the same price as the standard SuperBar at $89.00.

Question:

How do you insure that the SuperBar will fit the various miter slots since they are made in high production and not very accurate?

Answer:

The SuperBar is made from injection molded plastic with a U.S. Patented adjustment system that insures glass smooth motion within the table saw miter slot. It has both coarse and fine adjustments. The fine adjustment is spring loaded to insure glass smooth motion.

Question:

I have a dial indicator, can I buy the SuperBar without the dial indicator?

Answer:

Sorry, the SuperBar base is not sold separately. It is only sold only with the dial indicator. The reason being that this dial indicator was selected from over eighteen different indicators. The indicator has the following features.

• The indicator must have one inch travel

• The graduations on the dial face must be to .001 [1/1000] inch.

• The indicator must have a centered lug back mounting to allow a 1/4 inch diameter screw mounting.

• The stem must have special threads to allow installation of the one and two inch extensions that are supplied with the kit.

• The SuperBar kit has special hardware that works only with this dial indicator.

Question:

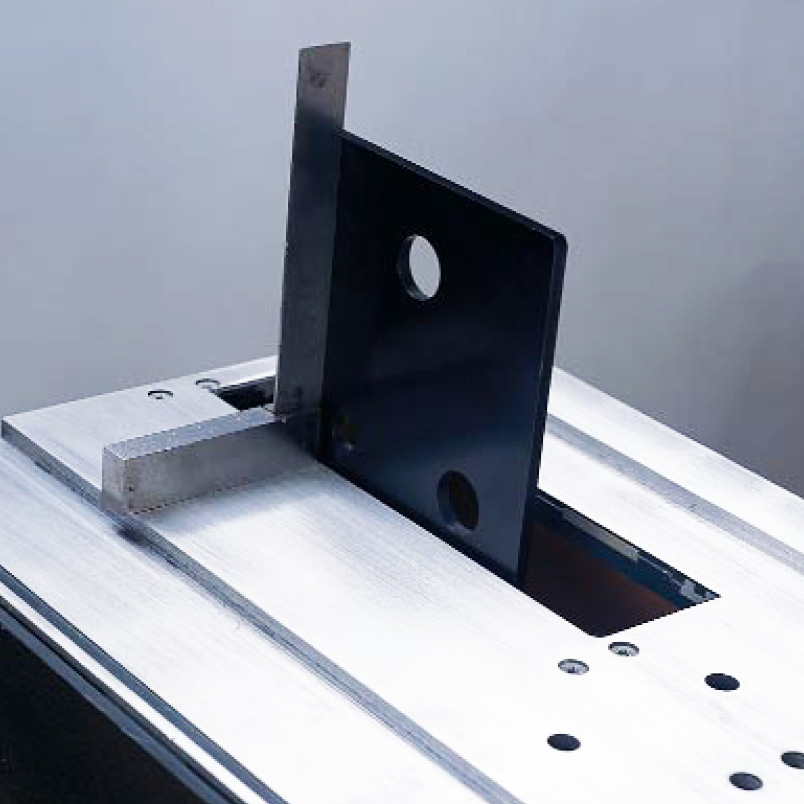

What equipment will the SuperBar tune?

Answer:

It was designed primarily to align and tune the tablesaw.

• It will check motor arbor run out, to be sure it is within specification

•It will check saw flange mount for run out; this could cause saw blade wobble

•Align the saw blade [or MasterPlate] parallel to the miter slot within thousandths of an inch.

• Square the saw blade [or MasterPlate] to the tablesaw surface.

• Center the splitter to the saw blade.

• Square the miter gauge to the saw blade.

• Align the scoring blade [ if applicable] parallel to the miter slot and centered to the blade.

• Align the rip fence parallel to the miter slot.

• Adjust the fence to any required toe-in, toe-out dimension recommended by your saw manufacturer.

• Check the rip fence for warpage.

• Once everything is aligned correctly, install the saw blade and rotate by hand to check it for run out.

• The dial indicator could also be used to check run out on drill presses, shapers, lathes, routers, band saw wheels etc.

Question:

How accurate is the SuperBar?

Answer:

The dial indicator reads to within .001 [1/1000] of an inch. As a comparison, the human hair is two one-thousandths of an inch thick [.002]. A piece of bond paper or copy paper is approximately .003 inches thick.

We suggest you go to the documentation page and download the SuperBar instruction manual.

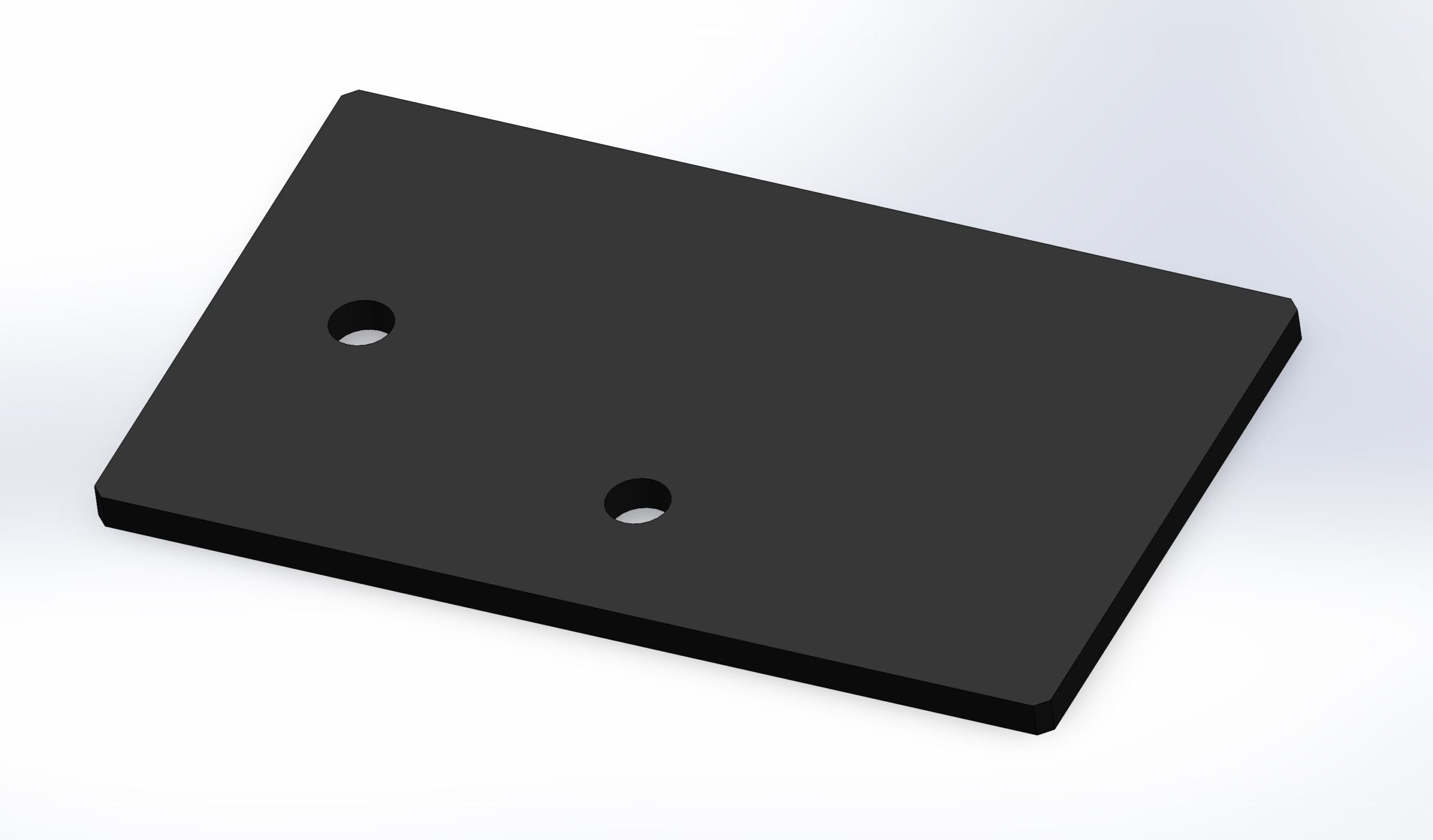

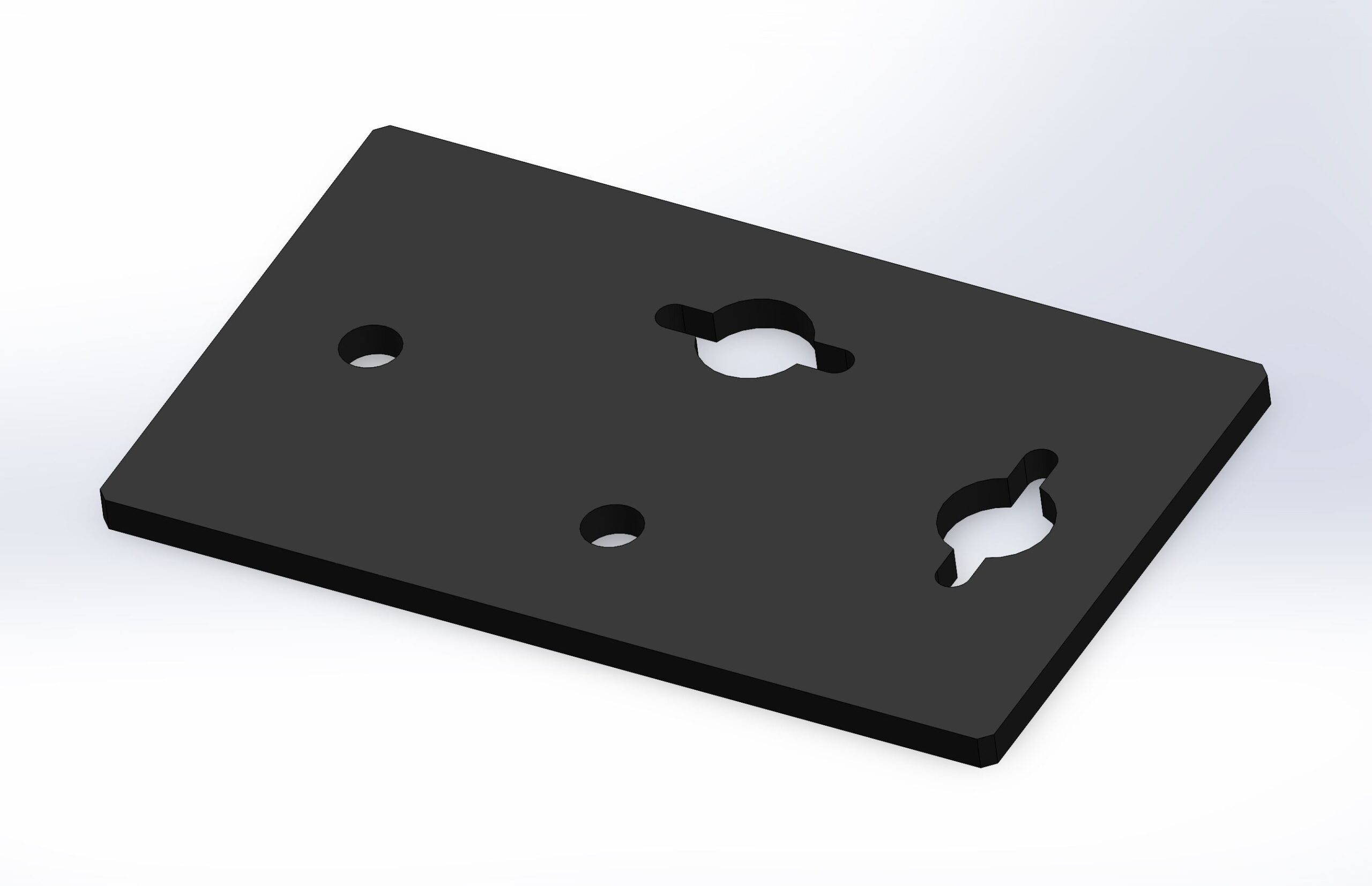

MasterPlate Frequently Asked Questions -FAQ

Question:

Why do I need the MasterPlate to tune up my tablesaw?

Answer:

Until now, we have all used the saw blade to align our saws. The saw blade was designed for cutting wood and plastic, not for aligning and calibrating your equipment. Using a saw blade to align your system gives you very little distance to measure parallelism to the miter slot, because of the saw carbide tips, gullets, anti-noise slots and gum and pitch build up in the saw blade. The saw blade, even when fully extended gives limited distance to measure because of the arc of the blade. The MasterPlate gives you a full 10 inch x 6 inches of precision flat, smooth surface to align your systems.

Question:

What equipment can I align with the MasterPlate?

Answer:

Primarily, the tablesaw and radial arm saw. If the blade cover [shroud] on the chop saw, sliding compound miter saw and miter saw allow the MasterPlate to fit under the shroud, these saws may also be tuned.

Question:

What is the material and coating?

Answer:

The material is 1/4 thick aluminum plate. This material is used by toolmakers because it is very dimensionally stable. It is stress free, since it is cast aluminum and not cold rolled wrought aluminum. The finish is a black anodize which is an excellent protective coating, used in the aerospace program.

Question:

How flat and parallel is the MasterPlate?

Answer:

The plate is within .002 thousandths of an inch both flat and parallel over ten inches. Far exceeding the basic requirements of woodworking machinery. The MasterPlate is disc ground to exacting tolerances. This means that the MasterPlate is precision ground between two grinding surfaces at the same time to insure flatness and parallelism.

Question:

Does the MasterPlate need special handling?

Answer:

Yes. The MasterPlate must be treated like any fine tool, since mishandling will cause it to go out of tolerance. It must not be bumped, or dropped. It should be treated like a precision tool.

Question:

What size saw arbors will the MasterPlate mount to?

Answer:

The MasterPlate will accommodate both 5/8 and 1.0 inch diameter arbors. We also make a 30mm diameter version. |